Capabilities

Manufacturing and servicing facilities

We are leaders. In technology. In innovation. We offer highly engineered solutions and services, exporting the AMPO WAY wherever our manufacturing and servicing plants are worldwide. Wherever our people are.

At AMPO we are committed to being where our customers need us and are continuously developing new localization programs to support our customers in terms of service and technology, all over the world.

We currently have manufacturing and servicing plants in:

IDIAZABAL

(GIPUZKOA, SPAIN)The AMPO HEADQUARTERS are located in Idiazabal (Spain), covering an area of around 45,000 square meters, with the following facilities:

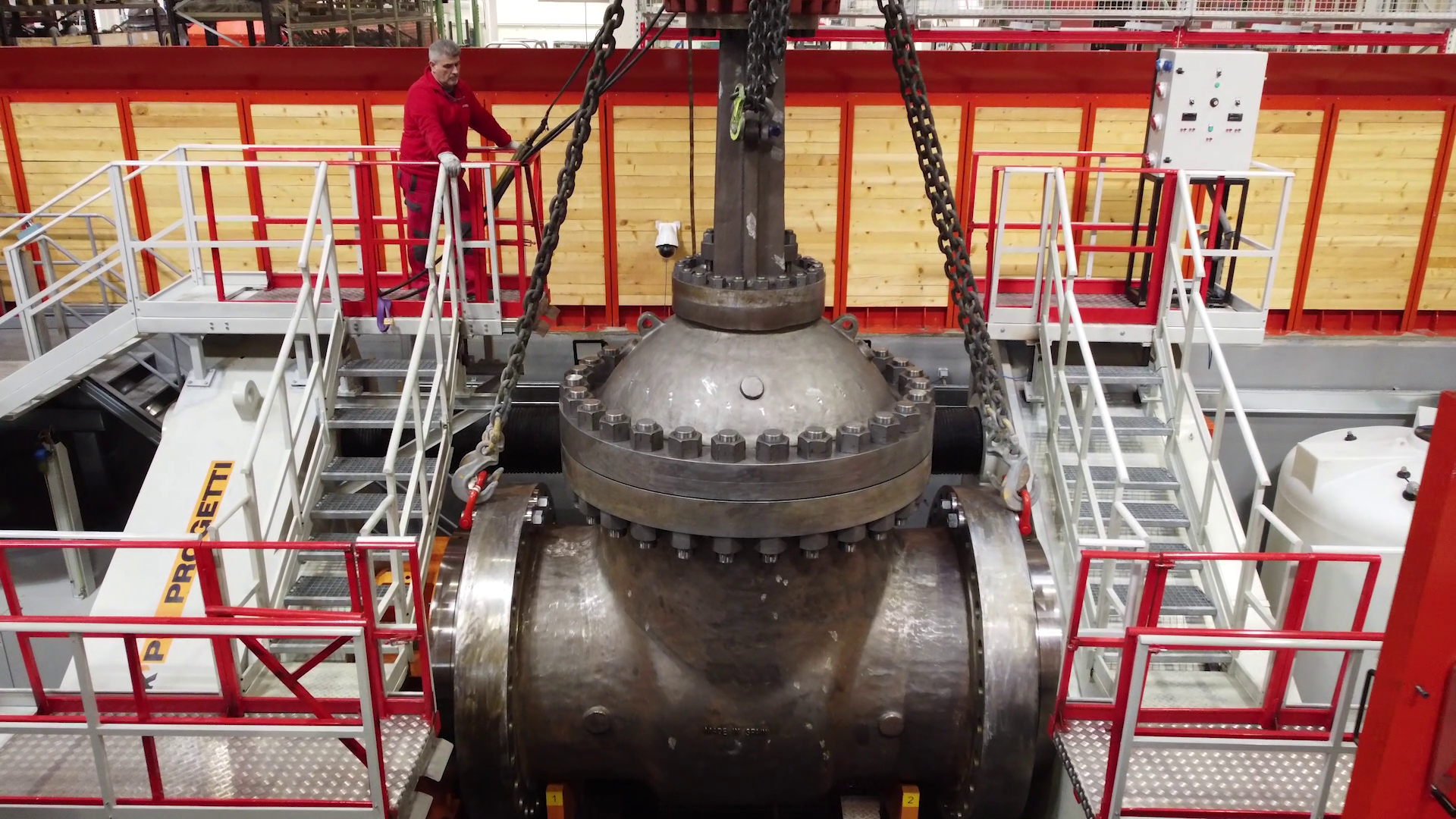

- Cutting edge valve assembly, testing, painting and packing facilities, fully equipped with the most advanced technologies, which gives us fully integrated process capacity. This allows us to develop and manufacture new, highly engineered solutions, and also to repair and retrofit any existing valve at our facilities in Idiazabal.

- Our own Foundry: AMPO has four production lines (Sand Molding, Ceramic Molding, Centrifugal Castings, Shaped Centrifugal Castings), each of which uses the most advanced technologies, with a global production capacity of 1110 tons per month. AMPO FOUNDRY & FORGINGS is considered one of the very best European foundries.

- A new 12,500 m2 cutting-edge machining plant, where we also develop internal weld overlay and cladding operations.

INDIA

AMPO INDIA has been located in Coimbatore (India) since 2008.

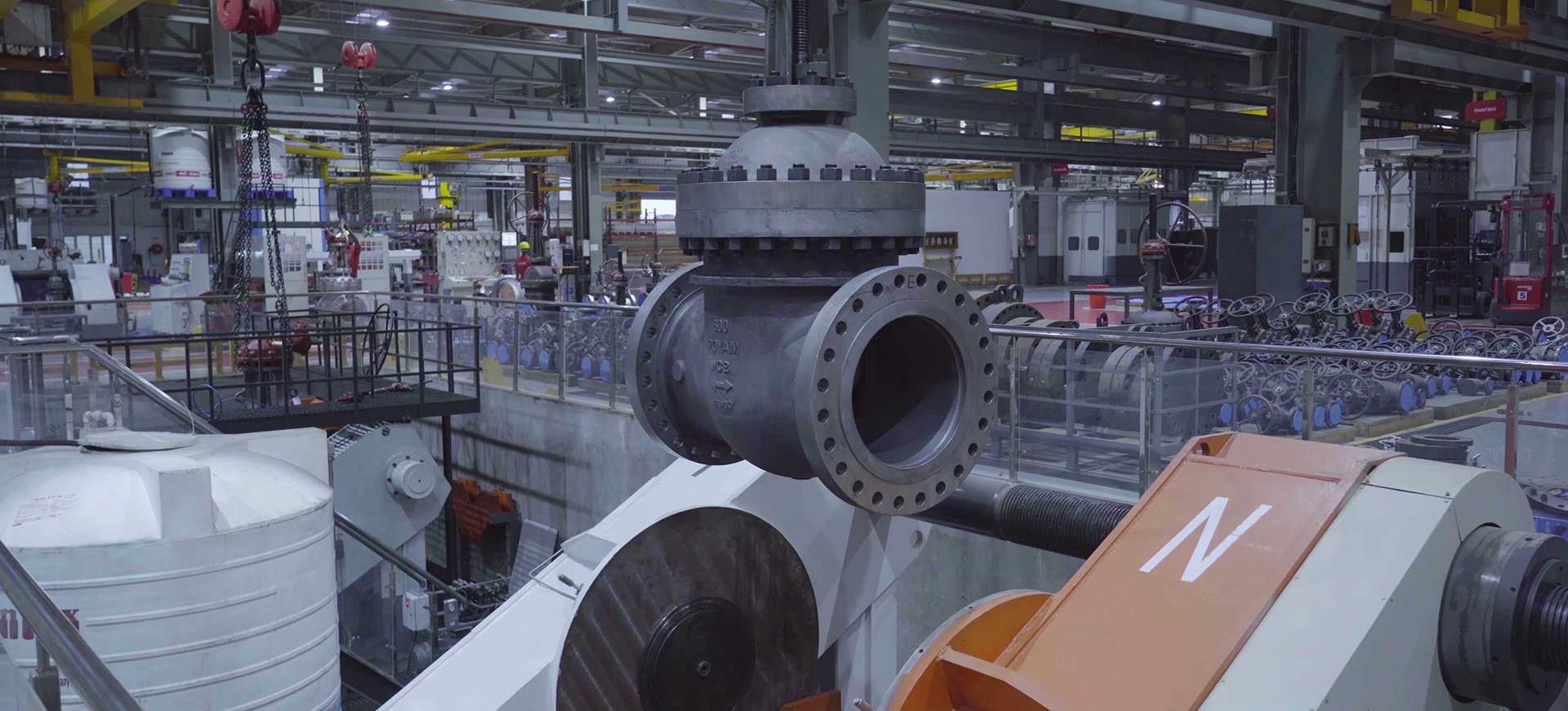

In 2017 we opened our new plant, covering an area of around 15,000 square meters with valve assembly, machining, welding, testing, painting and packing facilities. We have more than 300 talented employees on site here, with the most advanced equipment technologies on the market to produce up to 72” size valves, with cranes up to 50 tons, test benches for 2500# valves, etc. Here we not only produce new valves and solutions, but are also able to repair and/retrofit existing ones.

KSA

AMPO ARABIA is located in Dammam 2nd Industrial City (Kingdom of Saudi Arabia).

Aiming to become a strategic partner and share Saudi Arabia’s Vision 2030, AMPO POYAM VALVES is now part of the local KSA industrial cluster, transferring technology and know-how and creating quality job opportunities for Saudi nationals through extensive training and development programs.

AMPO ARABIA, which is already approved by ARAMCO, designs and manufactures highly engineered gate, globe, check and ball valves, repairs and retrofits existing valves, and offers best-in-class services and technologies for the local and GCC regional energy industry.

This local facility impacts positively on improved lead times and after-sale services to meet the demands of current and future projects in the GCC region.

The new 5,000 sqm plant includes valve assembly, machining, welding, testing, painting and servicing facilities.

KAZAKHSTAN

AMPO KAZAKHSTAN is located in Atyrau, Kazakhstan.

Its main aim is to become a strategic partner for Kazakhstan and the Caspian region, supporting local customers in terms of service and technology, and focusing also on critical valve maintenance services for key projects in the country. AMPO POYAM VALVES is transferring technology and know-how as well as building local manpower and skilled expatriate labor, designing specific and continuous training programs.

Top-notch facilities, resources and the latest available technology and equipment for the development of highly engineered ball, gate, globe and check valves can be found in AMPO Kazakhstan, alongside a dedicated team of highly qualified, experienced and customer-oriented field engineers with reliable, and traceable global experience, guaranteeing a prompt response to local customer needs, including technical support in the start-up stages, commissioning, engineered solutions, equipment selection, preventive and predictive maintenance, troubleshooting and training.