News & Media

NEWS

AMPO POYAM VALVES has supplied hundreds of severe service and high-pressure service valves over the last 55 years. AMPO POYAM VALVES has extensive experience working with different overlay materials and technologies. It is thanks to our high-tech design and our technical and manufacturing capabilities that our customers trust AMPO.

The overlays protect the different components of the valves against wear, erosion, corrosion and other degradation mechanisms, putting at risk the durability and effectiveness of the product. Depending on the service conditions, whether it is a valve intended for slurry transportation pipes, a valve working under high temperature and pH acid conditions, or a valve intended to handle saltwater, the solution to be adopted may be completely different. In fact, the same overlay may not be applicable to different parts of the same valve.

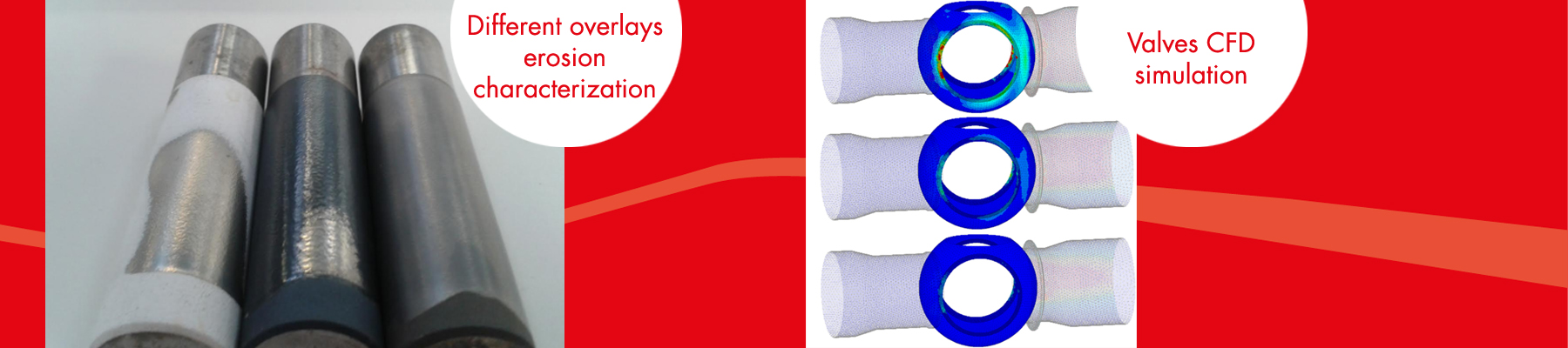

To provide the optimal solution for the service, AMPO POYAM VALVES relies on its knowledge, gained from experimental characterization on its erosion test bench, and on computational fluid dynamics simulation (CFD).

The AMPO POYAM VALVES Innovation team has the capability to characterize, on its own test bench, different materials and coatings under very severe erosion conditions trying to simulate the service conditions of mining transportation. High speeds and concentrations of particles and in neutral/alkaline environments have been used to characterize the wear rate of each material-overlay and to select the best solution for each case.

These same tests are used to feed the necessary parameters into fluid dynamic simulations that can predict valve wear. By developing these simulations, we are able to offer to our customers which will be the most critical points of the valve, as well as to predict its durability depending on the overlay-material used.

This type of project enables AMPO to offer a product with added value based on providing a customized solution to the customer’s needs.