News & Media

NEWS

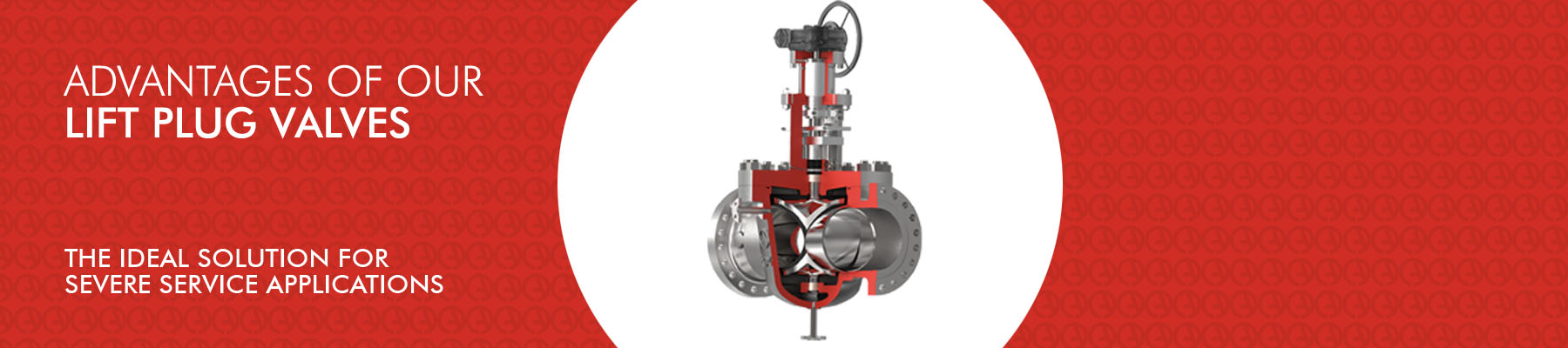

Our lift plug and switch plug valves have been designed specifically for the most severe conditions containing heavy crude feedstocks subject to high temperature and coke formation, but in order to offer a maximum interchangeability of valves in refineries and petrochemical plants, we have implemented a continuous improvement plan which includes complying with ASME B.16.10 face to face dimensions.

By means of this option, we are able to offer the refiners a great and interchangeable solution to replace existing isolation or switch ball valves by lift plug and switch plug valves.

In addition, our yoke and lift/turn mechanism has been designed to allow maintenance works when the valve is inline, so there is no need for the disassembly of it from the line for its replacement. A guided design permits the valve to be installed vertically or horizontally and for high pressure differential, our integral plug-stem component makes a stronger and a more robust design avoiding hysteresis and misalignments. Furthermore, low operation torques are achieved because there isn’t contact between closure surfaces during the operation compared with ball valves, and consequently, the wear is less. Therefore, no lubrication is required for a proper operation of the valve. It has a low steam consumption since flushing is required only during operation, less flushing points than in a ball valve are required, the flushing system keeps seating surfaces clean and seats are protected from erosion in the open and closed position.

So, we can consider our lift plug and switch plug valves as the ideal solution for severe service applications.